Description

Advantages:

Durability: Side bow chains are known for their high strength and excellent durability. The precisely designed link structure and the selection of high-quality materials enable the chain to withstand the pressure and impact forces under extreme working conditions. Whether running at high speed or under heavy load conditions, side bow chains can maintain their integrity and functionality and are not prone to breakage or deformation.

Fatigue resistance: Side bow chains excel in fatigue resistance. Its materials undergo special heat treatment and surface treatment processes such as carburizing, nitriding or galvanizing, which not only enhances the wear resistance of the chain but also improves its fatigue strength. Experimental data show that the life of side bow chains after these treatments can be extended by more than 30% under high-frequency vibration and cyclic loads.

Easy to maintain and replace: Compared with traditional chains, the design of side bow chains simplifies the maintenance process. The self-lubricating properties in its structure reduce the need for frequent lubrication, and the modular design makes it easier to replace the links. When a part of the chain is severely worn, there is no need to replace the entire chain, only the damaged link can be replaced, which greatly reduces maintenance time and cost.

Applications:

Side bow chains are widely used in a variety of industries involving curved conveyors, diverters, and sprocket drive systems. Some common applications include:

Conveyors: Side bow chains are widely used in conveying systems, especially in industries where the conveying path requires frequent turns and bends. They provide the necessary flexibility to navigate complex routes while maintaining smooth and efficient operations.

Packaging equipment: In packaging equipment, side bow chains are essential for moving products through various stages of the packaging process. Their flexibility allows the equipment to handle products efficiently and ensures a seamless packaging process even when the conveying path is not straight.

Food processing: Side bow chains are also commonly used in food processing applications. These chains have the ability to bend and turn, so they are able to transport food to different processing stages without causing damage. Their design ensures hygiene and cleanliness, suitable for environments with strict hygiene requirements.

Professional side bow chain manufacturer:

Experienced: We have many years of manufacturing experience and have accumulated a wealth of technical and industry knowledge.

High-quality products: We are committed to providing high-quality side bow chain products. The use of high-quality raw materials and advanced manufacturing processes ensures the durability and reliability of the products. Products undergo strict quality control to ensure compliance with international standards and customer requirements.

Customization capability: We are able to customize side bow chains according to customer needs. We have a professional design team and production equipment, which can be customized according to customer requirements to meet the needs of different industries and applications.

Fast delivery: We have an efficient production and supply chain management system, which can deliver customer orders in time to meet customers' urgent needs.

Good after-sales service: Provide comprehensive after-sales service, including product installation guidance, technical support and repair and maintenance. Our team is always available to help customers and solve problems.

Qianjiang Chain is not only a side bow chain factory and company, we are your partner on the road to success. We are committed to providing the best side bow chains solutions for your industry.

What is a side bow chain

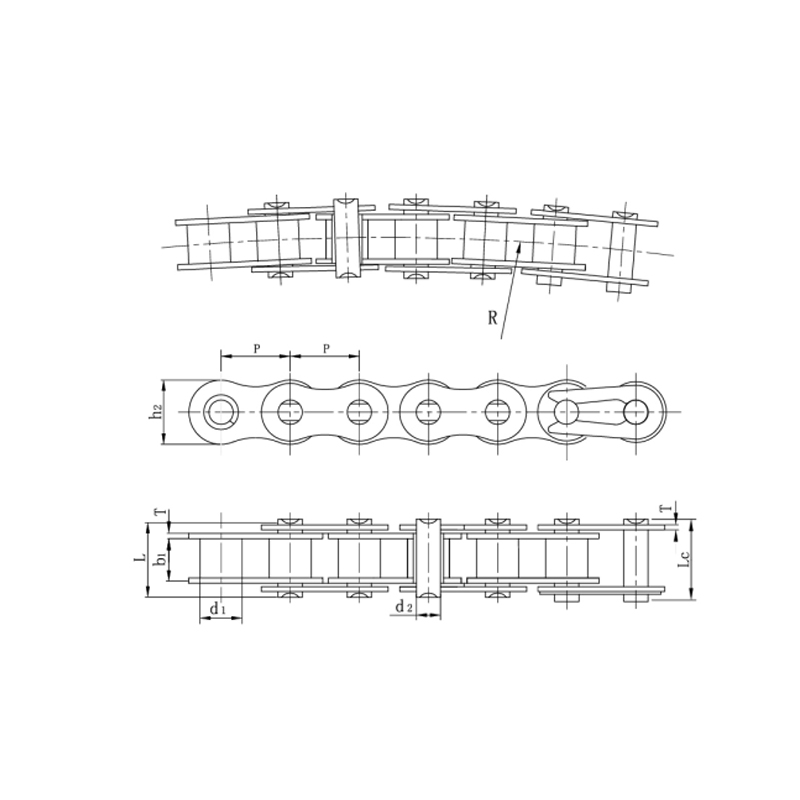

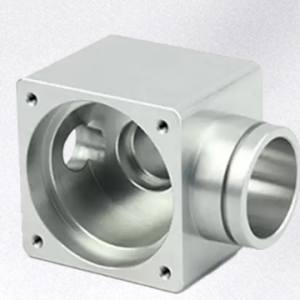

A side bow chain is a chain specially designed to transmit power or carry loads on a curved track. Its structural features include symmetrical tapered pins with a central running surface that allows the inner and outer chains to operate at an Angle. side bow chain bars are commonly used in conveyor or tow chain systems that require curved tracks, can have different bow radii, and their structural dimensions meet ISO 606 standards, so they can be used with standard sprockets.

In addition, side bow chain bars have lower tensile strength and life expectancy than traditional chains due to special pin designs, which limits the load-carrying capacity of chain joints. In some applications, side bow chain strips can use special lubricants or special coatings, and may be fitted with bending attachments, flat plastic conveyor plates, or extended pins.

The side bow roller chain is a type of side bow chain bar, which is widely used in the food industry, the automotive industry and the pharmaceutical industry. The chain is capable of curved movement and is suitable for curved conveyors with attachments or driven by curved rollers.

side bow chain maintenance

The maintenance of side bow chain needs to pay attention to the following points:

1. Cleaning and drying: Keeping the side bow chain clean and dry is the basic maintenance step. Clean dirt and grime regularly to avoid the accumulation of dust, dirt and grime to prevent corrosion and wear.

2. Lubrication: Lubrication of the side bow chain with appropriate lubricants, especially in the bearing surface and connecting rod area, can effectively reduce friction and extend service life. Lubrication should be done regularly depending on the frequency of use, such as once a week for heavy use and once a month for low frequency use.

3. Inspection and maintenance: Regularly check whether the chain teeth and tail of the side bow chain are loose or damaged, whether the track is smooth, and whether the anti-slip device is effective. If any problem is found, it should be repaired or replaced in time to ensure safety and function.

4. Storage: When not in use, the side bow chain should be stored in a clean, dry place, avoid squeezing and impact, and away from corrosive substances. Maintaining good storage conditions helps to extend its service life.

5. Anti-corrosion and anti-rust: For metal parts, special attention needs to be paid to anti-rust treatment, which can be protected by anti-rust oil or lubricant. At the same time, avoid exposing the side bow chain to moisture or corrosive environments.

Through the above steps, you can effectively maintain and maintain the side bow chain to ensure its good performance and long service life in various working environments.

side bow chain structure features

The side bow chain has the following structural features:

1. Design standards: Side chain bow bars are usually constructed according to DIN 8188 and ISO 606 standards, and sizes vary in pin and outer width.

2. Structural features: The side bow chain bar has a symmetrical conical pin, which makes the inner and outer chain run at a certain Angle on the curved track, so as to transmit power or carry load. The gap between the pin and the sleeve is large, allowing the chain to bend sideways into a bow.

Application: The side bow chain is suitable for conveyor chains or system tow chains that require curved tracks, such as those used in conveyor and transport systems, and can be fitted with various brackets or special belts [[4].] In addition, side bow chain bars can be used for conveyor chains in a variety of applications, especially where a proper chain guide is required when transferring loads on curved tracks.

3. Material and specifications * : * The material of the side bow chain can be stainless steel, the pitch range is from 12.7mm to 31.75mm, the specific specifications comply with JIS, DIN/ISO standards.

4. Performance limitations: Due to a special gauge, the tensile strength and life expectancy of the pin side bow chain are lower than that of the traditional chain, which limits the load carrying capacity of its joints.

5. Additional features: The side bow chain strip can be fitted with bending accessories, flat plastic conveyor plates or extended pins as required, and can use special lubricants or special coatings.

These characteristics make side bow chain strips unique in specific application scenarios, especially where flexible bending and complex track design are required.

side bow chain material composition

The material composition of side bow chain consists mainly of stainless steel and acid-resistant high-quality steel, which have material corrosion resistance and are suitable for a variety of industrial applications. The side bow chain bar is designed according to DIN 8188, and its size varies mainly in the pin and outer width, with a symmetrical tapered pin design to accommodate power transmission or load bearing on curved tracks.

side bow chain Supplier Manufacturer How to choose

When choosing a side bow chain supplier or manufacturer, there are several factors to consider to ensure you choose the partner that best suits your needs. Here are the key factors to consider when choosing a side bow chain supplier:

1. Material quality: Choose suppliers that use high-quality materials (such as stainless steel, brass and aluminum) that ensure product strength, durability and corrosion resistance.

2. Expertise and experience: Preference is given to suppliers with extensive experience and expertise in the field of side bow chain manufacturing, who are usually able to provide products that conform to the latest technology and manufacturing.

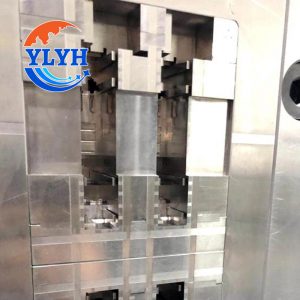

3. Manufacturing capacity: Ensure that suppliers have advanced facilities and equipment to produce accurate and consistent products and meet large-scale production needs.

4. Customer satisfaction: Choose vendors who offer exceptional customer service, customized solutions, and strong warranty support, which shows that they can deliver on their promises and deliver a positive customer experience.

5. Industry reputation: Good industry reputation and customer feedback is an important basis for selecting suppliers, indicating that suppliers can provide reliable products and services.

6. Quality Control: Select suppliers who implement strict quality control measures to ensure that products meet the highest standards, including thorough testing and inspection processes.

7. Customized solutions: Suppliers that can provide customized design and production capabilities according to specific needs are more trustworthy.

8. When pricing goods and delivery: When comparing different suppliers, you need to consider price and delivery time. While cost is an important factor, balancing cost with quality is just as important to ensure the best value for your investment.

By combining the above factors, you can make an informed choice and find a supplier that can provide a high quality side bow chain, thus ensuring the quality of the final product and customer satisfaction.

Sell side bow chain factory how to choose

When choosing to sell side bow chain factory, consider the following aspects:

1. Market awareness and brand influence: Choose those manufacturers with high visibility and good reputation in the industry.

2. Product quality and technical support: Choose those who provide high-quality products and can provide technical support manufacturers.

3. Production capacity and scale: Select those manufacturers with larger production capacity and advanced production equipment to ensure that they can meet the needs of large-scale orders.

4. Customer reviews and case studies: Review other customer reviews and use cases to understand the actual performance of the manufacturer.

5. Price and cost performance: Compare the price and cost performance of different manufacturers, choose those who are competitive in price and cost-effective manufacturers.

Considering the above factors, choosing the right side bow chain factory requires a comprehensive consideration of its market position, product quality, production capacity, customer feedback and price advantage.

What are the advantages of the side bow chain

The side bow chain has the following advantages:

1. High flexibility: side bow chain design allows horizontal bending, easy to achieve bending movement, and can use standard gears. This flexibility makes it useful in applications where direction changes are required, such as radius turns and vertical directions in conveying systems.

2. Adaptable: The side bow chain is suitable for a variety of applications, including conveyor chains or tow chains that require curved tracks, and can be fitted with bent accessories, flat plastic conveyor plates or extended pins depending on the application requirements.

3. Standardization of structural dimensions: The side bow chain's structural dimensions comply with ISO 606 standards, so it can be used with standard sprockets, which improves its compatibility and convenience in industrial applications.

4. Safety performance: Offset rollers and adapted joint geometry are used in the side arch cumulative chain design to ensure optimal load transfer during radial link travel, thereby improving link performance and safety.

These advantages make the side bow chain have a wide range of applications in industry and conveying systems.

Reviews

There are no reviews yet.